Biomaterials can offer a solution to one of the world’s most polluting industries — fashion. It’s responsible for more carbon emissions than international flights and shipping combined, amounting to 10% of all greenhouse gasses emitted globally, according to figures from the United Nations Environment Programme (UNEP).

The carbon-intensive production of animal hide for leather and plastic for synthetic clothing also play a major role in the pollution caused by the fashion industry. Yet leather is often left out of the sustainability conversation, or the fact that tanning, dying and treating animal hides requires toxic chemicals that are harmful to both the environment and human health.

Fortunately, it’s becoming increasingly possible to replace both leather and plastic with alternative materials like mycelium, the thread-like underground root structure of fungi, as well as tree bark and cactus. Similarly, algae-based bioplastics are replacing sequins and other plastic materials.

The Possibilities of Biomaterials

Brands creating products from biomaterials are answering the call for greater sustainability in the fashion industry. While many of these new biomaterials are either prototypes or in the early stages of research and design, and far from mass production, biomaterials are challenging the fashion industry to reimagine ways it can reduce its colossal carbon footprint through alternative fabrics.

MycoWorks: Mycelium “Leather”

Using the magic of mycelium, innovative manufacturers are creating leather-like materials derived from fungi — that is neither plant nor animal — at a lower carbon cost than traditional animal hides or plastics.

MycoWorks has created Reishi — a product that can be treated and manufactured like leather while outperforming leather in strength and matches leather in durability and appearance.

Founders Sophia Wang and Philip Ross developed a process that feeds agricultural waste such as sawdust to Ganoderma, a wood-eating fungus species, to coax it to grow mycelium cells in a dense, intertwined structure. Left alone, this mycelium would form mushrooms, but by controlling temperature, humidity and other environmental factors, the mycelium instead produces sheets of durable yet mailable fibres.

“Reishi is not leather. Reishi is more than leather,” said Matt Scullin, chief executive of MycoWorks. “We’re sort of limited by the vernacular right now. It feels like leather, it looks like leather, so we talk about it as leather — but it’s not leather.

“The leather and plastic-leather industries comprise one percent of global carbon emissions. I think the impact we can make with Reishi alone is actually quite significant.”

To this point, French luxury house Hermès has partnered with MycoWorks to reimagine its Victoria shopper bag in a leather alternative using Reishi. After a three-year collaboration design process, the revolutionary bag will be available from the end of this year.

“We could not imagine a better partner than Hermès to present our first object made of fine mycelium,” said Scullin. Hermès and MycoWorks share common values of craftsmanship, quality, innovation, and patience. Together, we saw the potential of this incredible material.”

Bolt Threads: Microsilk & Mylo

Founded in 2009 by David Breslauer, Dan Widmaier and Ethan Mirsky, Bolt Threads takes organic material like corn sugar or sawdust and feeds it to yeast or fungus, which then convert it into materials used to make Microsilk, a biomaterial that mimics silk spun by spiders. Mylo is Bolt’s “un-leather” bioproduct which grown from mycelium, the vegetative part of a fungus.

In 2019, Stella McCartney worked with Bold Threads to unveil a prototype, not-for-sale tennis dress made from Bolt’s Microsilk, and a prototype of her Falabella bag from Mylo for the Victoria & Albert Museum’s “Fashioned From Nature” exhibition. She’s been working closely with Bolt’s team ever since, forming a consortium with Kering, Adidas, and Lululemon to develop and scale Mylo’s development.

Until recently, it wasn’t possible to create pieces of Mylo that were large enough to cut into pants, and the early iterations were quite stiff. Now, McCartney has now unveiled the industry’s first-ever Mylo garments: a jet-black bustier and utility pants.

“We’d already done a bag, so I wanted to do the ready-to-wear to give a bit more insight into how much you can do with this material, and how it can be swept across the industry to actually replace leather,” McCartney explained. “And it’s just so much better for the planet”.

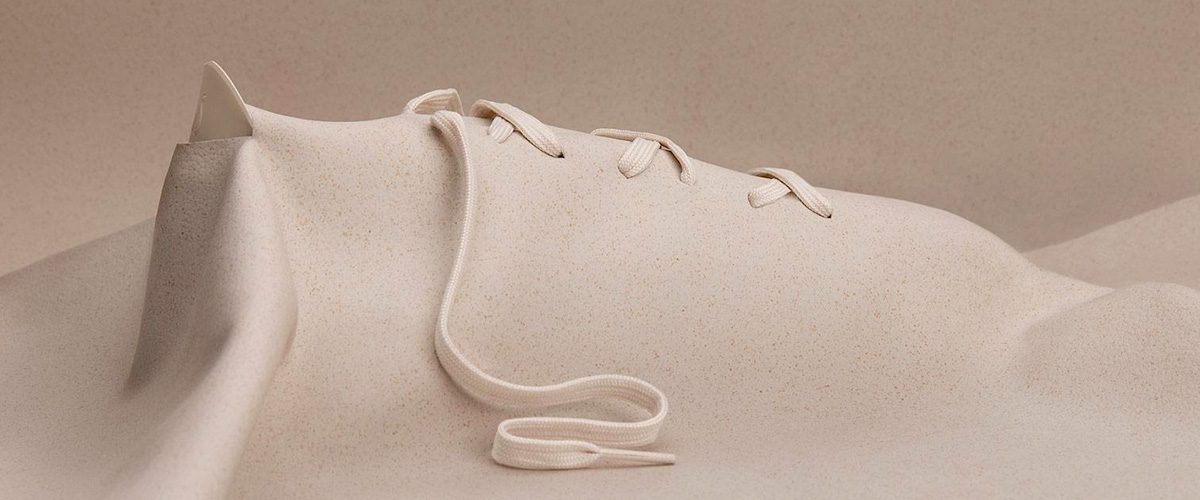

AllBirds: Plant-Based “Leather”

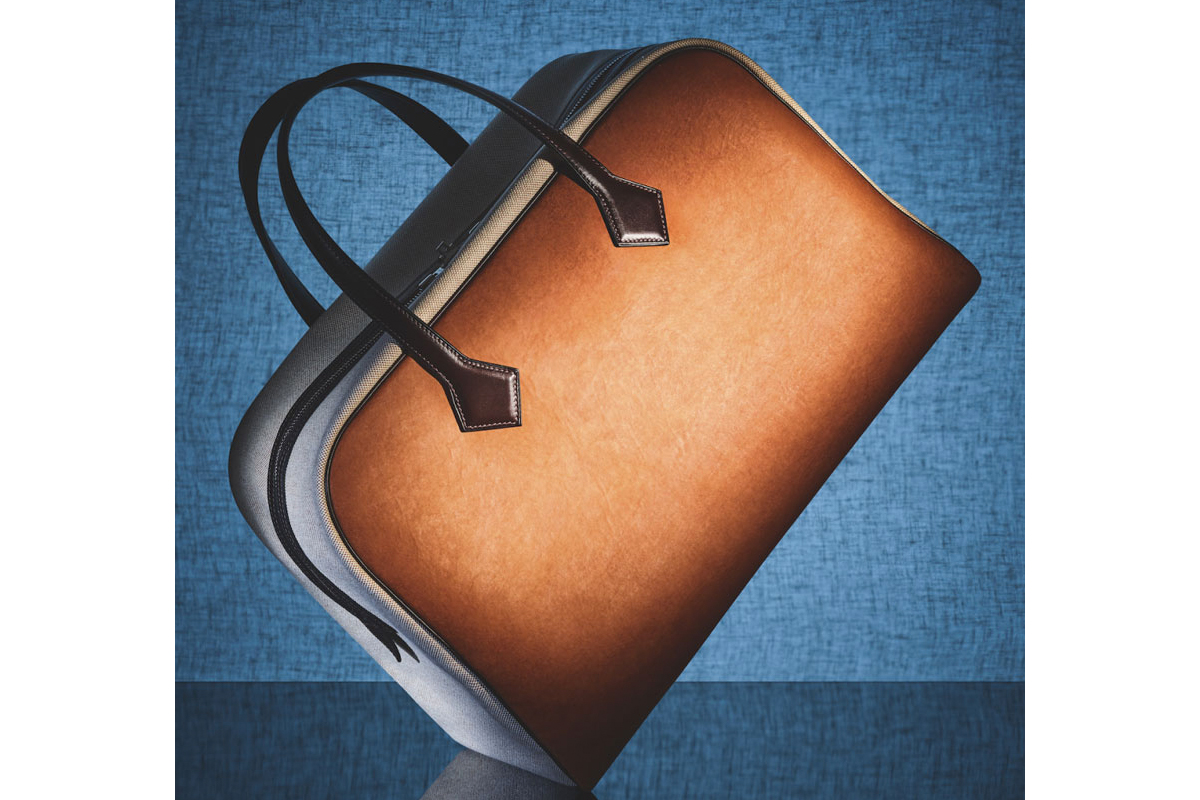

San Francisco-based footwear brand Allbirds is working on what it claims is “the world’s first 100 per cent natural plant-based leather alternative”.

Originally developed by material innovations startup Natural Fiber Welding (NFW) under the name Mirum, the plant-based biomaterial is now set to be turned into footwear that will hit shelves by December 2021.

Plant Leather is made from natural rubber derived from the sap of the rubber tree as well as vegetable oil, citric acid and fillers like cork and rice husks plus natural pigments. The biomaterials’ carbon impact 40 times lower than animal leather while producing 17 times fewer carbon emissions than plastic-based synthetic leather.

“Mirum is unique in that it is the only plant-based leather replacement on the market that does not contain any petrochemicals,” the company said.

Cactus “Leather”

Mexican startup Desserto, recently awarded by PETA for its cruelty-free innovation, has developed a naturally-tanned cactus-based organic material that is virtually identical to animal leather, not to mention a boon for the planet, as their production process uses a species of cacti called prickly pears that requires little water to grow and can easily survive in different climate zones.

Founded in 2019 by Adrian Lopez and Marte Cazarez, Desserto developed an animal-free and recyclable alternative by converting prickly pear cactus into smooth vegan leather without the need for herbicides, pesticides, or even irrigation, and is coloured with organic pigments.

In keeping with the houses’ efforts to achieve the sustainable goals listed in the G7 Fashion Pact, Parisian fashion house Karl Lagerfeld, founded by the iconic late German fashion designer and photographer, recently joined forces with model, actress, and activist Amber Valletta to co-create a sustainable 11-piece accessories collection for Spring 2021 using Desserto’s material.

“I’m convinced that Karl would have loved it,” said Valetta. “I love being able to continue his legacy – chic, bold and innovative. It’s exciting to see how thoroughly Karl Lagerfeld is researching sustainable practices and materials. They continue to impress me with their knowledge and commitment to design, and producing in a new and conscious way.”

Arsayo: Tree Bark “Leather”

Co-founded by founder brothers Ary and Jonathan Ohayon, French vegan brand Arsayo is dedicated to promoting ethical vegan fashion. Their mission is to provide a sustainable and ethical alternative to exotic skins from animals like crocodiles and snakes.

To that end, they have created Exotic Cork Skin, an eco-friendly substitute created from harvesting cork from trees. The line offers two designs (“Cork-odile” and “Snake Skin Cork”) that are featured on sleek backpacks ($249) made with cotton interiors and offered in various sizes.

“This new exclusive alternative is a tribute to the beauty of amazing exotic animals with the respect for their life and our environment,” Jonathan Ohayon said. “We want to set an example for the fashion industry, and show that animals shouldn’t be harmed for fashion.”

The brothers have also founded F.A.K.E. Movement, a global platform dedicated to promoting ethical vegan fashion.

Biomaterials are Used to Make Bioplastics & Carbon Sequesteting Clothes

There are many advantages to bioplastics. Firstly, they degrade far more quickly than petroleum-based plastics, taking three to six months to decompose fully compared to the hundreds of years regular plastic requires. Second, the carbon released by bioplastic as it decomposes is also equal to the carbon absorbed by the organic material it was made from, so the overall impact on the environment is close to zero.

One of the resources used to create bioplastics is algae, which, unlike fossil fuels, is not a limited (and heavily polluting) resource. Algae can capture ten times as much sunlight as terrestrial plants, and it grows fast with some species able to double their biomass within a few hours. It can be converted into powder, before being spun into a fibre.

Canadian-Iranian designer Roya Aghighi has invented a living, biodegradable fabric made from algae. Along with a group of scientists at the University of British Columbia (UBC), she has created Biogarmentry — a biofabricated textile that photosynthesizes, which purifies the air around it.

UBC claims it’s the first living and photosynthesizing textile, and has created a sheer, cloak-like garment from the material.

“Both fully compostable and more importantly, while living, the material will work to purify the air through photosynthesis,” said Aghighi on her website. “Since the life cycle of the living photosynthetic textile is directly dependent on how it is taken care of, the work challenges our current relationship to clothing, while acting as a catalyst for behavioural change.”

New York-based designer Charlotte McCurdy, a fellow at Rhode Island School of Design has also looked into algae and its potential to sequester carbon. She has created a carbon-negative raincoat made from a plastic-like material made of marine algae and other biodegradable biomaterials.

“The point is not to make a plastic out of algae,” McCurdy said at a talk organized by New York City’s New Museum. “The point is to sequester carbon, and it matters how we do that and how those systems scale.”

McCurdy is a member of One X One, an initiative that combines style and science to develop sustainable fashion. She recently partnered with designer Phillip Lim to create a seagreen petroleum-free dress, which represents the deconstruction and reconstruction of marine ecosystems. The sequins are made from algae and heat is applied to bind the algae together and form the bioplastic. This is then poured into moulds which become sheets. Once cooled, the sheets of bioplastic are finally cut into sequins.

The dress’ colour comes from dyes derived from organic material. The sequins are attached to a fishing net-like mesh created from a seaweed and bamboo fibre called SeaCell, created by natural textile suppliers PYRATEX. Finally, the garment is adorned with mother of pearl, resulting in a stunning statement of sustainable fashion, as eco-friendly as it is striking.

As promising and forward-thinking as these fashion initiatives are, it will take an adjustment of infrastructure to make sure the environment feels the full benefit of fashion made from biomaterials. Changing our relationship with clothing, from one of neglectful fast-fashion consumption to one that involves living clothes made from sustainable biomaterials is the future of fashion.

Stay with The Last Fashion Bible for the latest news and innovations in sustainable fashion.

Main image credit: AllBirds